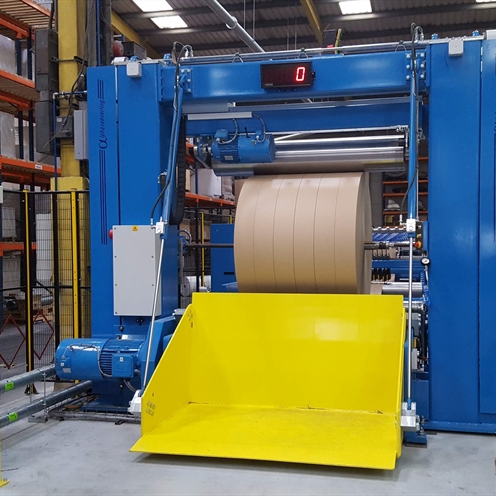

Automatic Turret Rewinders

ALPHAMATIC turret slitting rewinding machines offers a fully flexible option to automatic rewinding.

Designed for use with paper, laminates or films the machine can be supplied with varying levels of automation. Standard tapeless (cinching) start at the beginning of wind helps to prevent adhesive contamination in subsequent processes. Automated delivery out to a banding and printing head and automated unload of the finished roll is all achieved without any input from the operator.

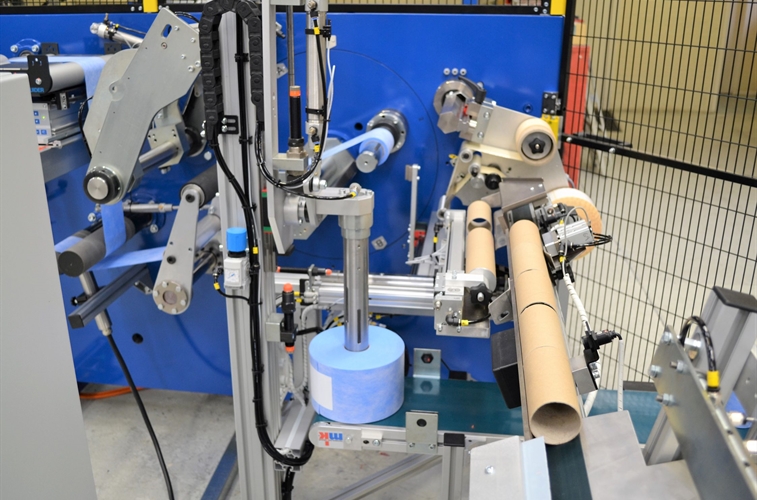

Configuration shown includes shafted unwind, with automatic core loading hopper, unload, and printing cell.

Standard Features

- Fully automatic roll transfer

- Tapeless (cinch) start on core

- Centre winding

- Precise tension control with torque controlled rewinding

- PLC control with touch screen interface and comprehensive recipe and maintenance systems

- Closed loop unwind tension control

- Quality engineered and manufactured in UK

Optional

- Coreless rewinding

- Rewind core sizes - 2" and 3"

- Roll closure by tape

- Roll closure by label

- Roll start by tape

- Slitting

- Automatic knife setting system

- Core and roll labelling

- Discharge to conveyor

- Auto bagging

- Wrapping systems to customer specification

- Label printing systems for cores, rolls and bags or boxes

- Rewind unloading systems

Typical Specification

| ALPHAMATIC - Turret slitter rewinder | ||

| Web width | 500 to 2,000 mm | 10 to 80 inches |

| Rewind diameter | 50 to 180 mm | 2 to 7 inches |

| Rewind core diameter | 50, 76 mm | 2, 3 inches |

| Unwind diameter | To 1,800 mm | 70 inches |

| Material thickness | 25 to 500 µm | 1 to 20 mils |

| Line speed (maximum) | 300 m/min | 900 ft/min |

| Operator interface | Colour touch screen | |

Typical Materials

| Coated Paper | Floorings | Non-wovens |

| Film | Textiles | Label stock |