Slit Spooling Machines

ALPHASPOOL slit spoolers efficiently convert mini jumbo rolls of film and tapes to level wound spools or bobbins with a precise computer controlled traversing mechanism and sensitive tension control.

The cantilevered unwind and rewind shafts provide quick roll change whilst the servo control systems ensure precise spooling. All Alpha spooling machines are of heavy duty construction for long life.

Pancake rolls may be produced on a slitter rewinder such as an ALPHALAB TWIN slitter or on a single knife log slitter.

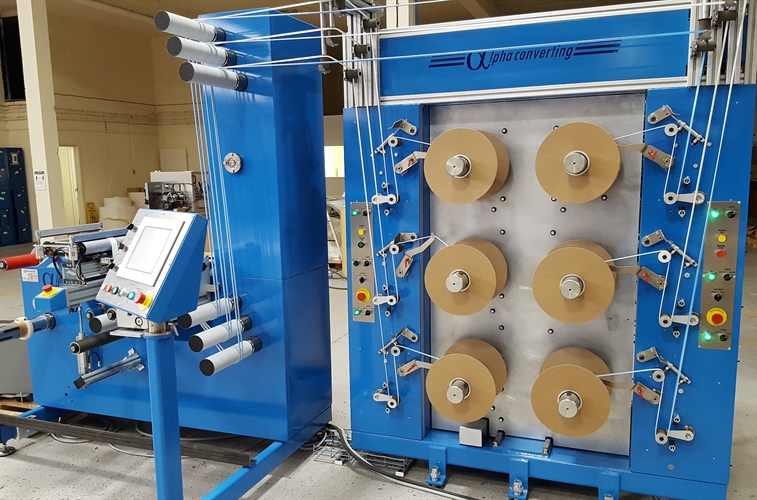

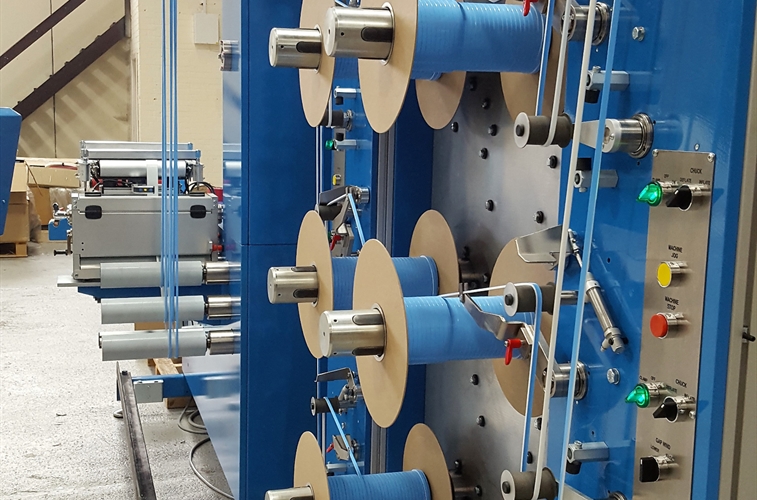

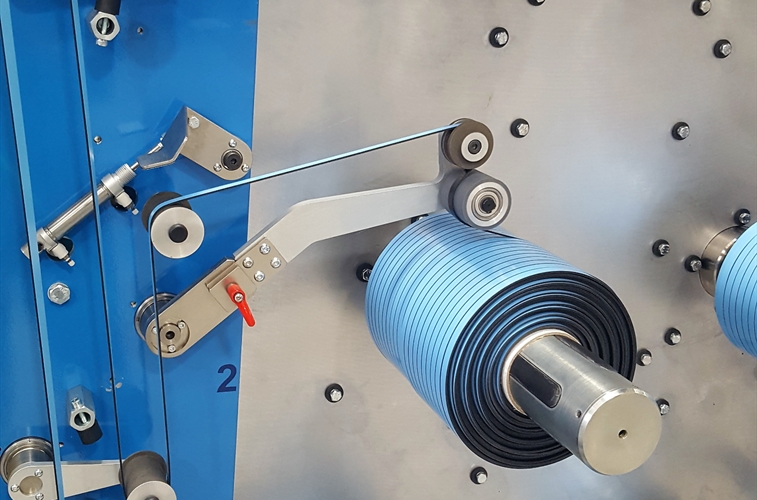

Examples shown:

- Twelve station modular spooler type ALPHASPOOL 6 configured for adhesive tapes and foams. Features cantilevered unwind with interchangeable slitting box, multiple pull rolls, and simple threading path.

- Multi-strand spooler for winding multiple reels on common shafts, for cables and tapes, or can be supplied with heavy duty shaft supports for winding of aluminium, brass or steel strips.

- Spooling of fingerlift product after slitting and removal of fingerlift portion. All rolls treated for running open adhesive of fingerlift. Heavy duty bobbins for high capacity running in the motor industry.

Standard Features

- Cantilevered unwind

- Auto stopping at unwind core

- Precision slitting

- Precise spooling tension with closed loop control

- Precise tape lay down with computerised traversing

- Modular construction for future expansion

- Touch screen control with recipe system

- Quality engineered and manufactured in UK

Optional

- Interchangeable slitting cassettes for razor, shear or score slitting

- Choice of rewind shafts for cores or spools

- Quick change rewind shafts

- Guide wheels

- Guide fingers

- Powered roll ejection

- Slitting to print alignment

- Low tack roll coverings for exposed adhesives

- Driven path rollers for low tension applications

- Automatic spool offload to trolley system

- Fingerlift removal

- Clean room installation

- Gap mode winding (non contact)

- Peel off roll (unwind only)

Typical Specification

| ALPHASPOOL Slit Spooler | ||

| Tape width | 0.8 to 150 mm | 0.03 to 6 inches |

| Tape thickness | 10µm to 10 mm | 0.4 mils to 0.5 inches |

| Filament diameter | 10µm to 5 mm | 3 mils to 0.2 inches |

| Unwind Roll diameter | 450 to 1000 mm | 18 to 40 inches |

| Spool diameter | To 1200 mm | To 47 inches |

| Spool width | 100 to 1200 mm | 4 to 47 inches |

| Speed | 400 m/min | 1,200 ft/min |

Typical Specifications

| Film - OPP, PET, PE, PVC | Medical | Foam tapes |

| Non-woven | Strapping tapes | Decorative tape |

| Self adhesive | Brass | Tear tape |

| Fingerlift tapes | Protection tapes | Security tape |

| Metallised film | - | - |