Narrow Web Slitter Rewinders

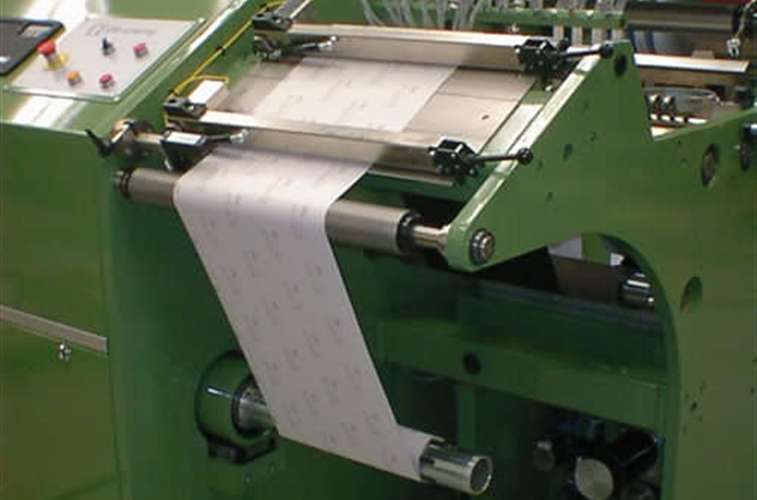

The ALPHALAB slitter rewinder with cantilevered winding shafts suited to narrow width slitting and rewinding or roll rework, typically used for narrow web or pressure sensitive tapes (PSA).

The cantilevered winding shafts are rigid during running yet provide for fast unloading and can easily be integrated with a variety of unloading systems. The ALPHALAB can be supplied with twin differential rewinding shafts for sensitive films and foams or with single winding shaft suited to labelstock, papers and rotary die cutting applications. The touch screen operator interface has simple recipe systems for multiple material types and slitting parameters.

Examples shown:

- Cantilevered unwinding shaft for quick roll loading with stainless splicing table and Alpha auto latching "Quickclamps".

- Interchangeable rotary die cutting and slitting stations provide maximum flexibility with matrix stripping and rewinding with a single shaft winder.

- Narrow width slitting with integrated coreless first winder to handle narrow trims.

Standard Features

- Cantilevered winding shafts for quick roll change

- Precise tension control with spacer-less differential rewinding shafts

- PLC control with touch screen interface and comprehensive recipe and maintenance systems

- Closed loop unwind tension control

- Quality engineered and manufactured in UK

Optional

- Automatic knife setting system

- Pneumatic layon rolls

- Integrated trim removal

- Die cutting

- Matrix rewinding

- Laser core positioning

- Single shaft rewinding

- Ultrasonic edge guiding or line guiding.

- Multiple knife systems (razor, score or shear)

- Stainless construction for clean room or food grade installations

- Powered roll push off

- Die cutting of piece parts

Typical Specification

| ALPHALAB | ||

| Web width | 300 to 600 mm | 12 to 24 inches |

| Rewind diameter | 300 to 500 mm | 12 to 20 inches |

| Minimum rewind width | 12 mm | 0.5 inches |

| Rewind core diameter | 76 mm | 3 inches |

| Unwind diameter | 800 mm | 32 inches |

| Material thickness | 10 to 500 µm | 0.4 to 20 mils |

| Line speed (maximum) | 300 m/min | 1,000 ft/min |

| Operator interface | 6" colour touch screen | |

Typical Materials

| Film - OPP, PET, PE | Laminates | Paper |

| Non-woven | Aluminium | Label stock |